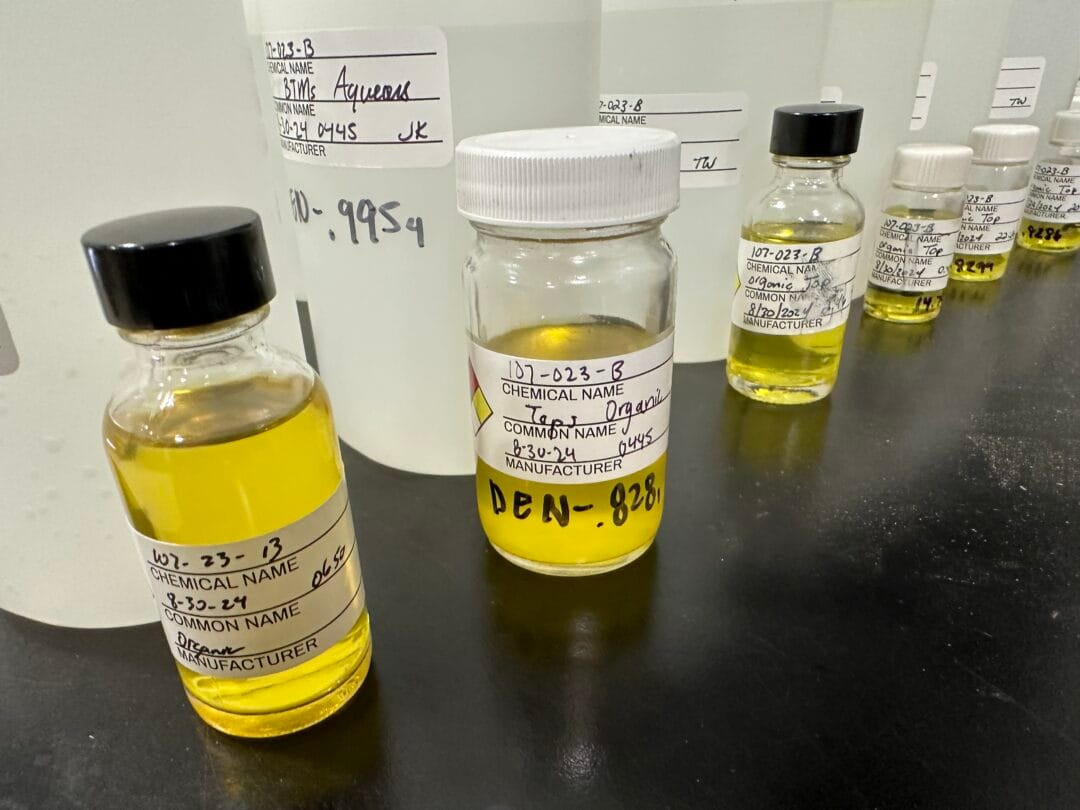

To support The Sustainable Air Fuel Production Goals (SAF) and increased national materials availability, global fuel technologies (UNIFUEL) have completed a successful five -month experimental project. The campaign showed the effectiveness and validity of the company’s recovery technology in SAF production, which can be chemically compared to traditional jet fuel from various renewable raw materials. The project was conducted in RPD technology facilities in Crossby, Texas, from August to December of last year. It produced approximately 100 liters of SAF sample materials under stable practical conditions, indicating an increase in technology. The campaign focused on converting methanol and ethanol into SAF and ethanol with the renewable Paravin bastha that was made via aqueous treatment and fatty acids (Hefa) into SAF. SAF samples were tested from Unifuel SAF accurately and are now analyzed in vital products, science and engineering laboratory at Washington State University to examine level 0 – the initial step of the SAF certificate.

“As an industry, it is important to continue to support and explore new techniques for progress in SAF to suit the functions of jet fuel derived from oil,” said Joshua Hein, Director of Biological Products, Science and Engineering (BSEL) at Washington State University. “The ability to make aromatic molecules and treat various raw materials through a single technical platform not only wear SAF production but also reduces production costs significantly, making them more economical and accessible to producers and airlines.”

The pilot resulted in two distinct SAF: SAK aromatic aromatic mixtures, which is composed of the basic essential mixture to maintain the compatibility of Paraffin with the formation of fossil kirosin, and Astm International, which is 100 % global technical. As a result, the SAF’s aromatic component can be mixed with a fresh, made from Hefa and FT Naphtha, with the SAF main stream of these units. This creates the opportunity to produce SAF directly in Hefa and FT units, which reduces the costs and complexity of logistics and help in adopting the industry.

“The impact of this experimental project reaches beyond technical verification,” said Alexei Peltiukov, CEO of Universal Fuel Technologies. “There is a great value of recovery is that it contributes to making SAF to be completely switched with fossil flying fuel once ASTM is approved. Due to its aromatic properties, which are necessary to comply with aircraft today, it can be mixed with increased pressure on the device. It contains costs, technologies such as recovery can be it is very important in increasing the production of sustainable aviation fuel to keep pace with the demand.”

Fluiciforming provides many options for the production of SAF, which makes it particularly adaptable to various renewable fuel scenarios. The experimental campaign was validated from ethanol to Jet (ETJ), methanol to Jet (MTJ), and renewable methods in the production of Navatha with ethanol to Jet (NetJ), providing flexibility in choosing raw materials. Due to low energy and hydrogen requirements in technology, unifuel is able to recover to be the cost of the current ETJ operations. Moreover, the operators of the renewable fuel factory allows for low-value secondary oil upgrade from the current Hefa or Fischer-Tropsch (FT) to create a high-value aromatic SAF that can be mixed in fully prepared artificial jet fuel.

“Samples from UNIFUEL SAFs appear from UNIFUEL, a promise to move forward with full certificates such as flight turbines,” said Harrison Yang, Assistant Professor at Washington State University at Washington State University.

The UNIFUEL team has completed over a decade of research and extensive tests on the recovery technology. With UNIFUEL moved to the next stage, samples from the sculpted SAF are prepared during the campaign to submit an ASTM certificate. The process of issuing these certificates is necessary to verify the health of safety and performance properties, which ultimately determines their ability to use commercial aviation.