- Measurement of automatic goods: CIND Dimensioner uses AI and Stereo cameras to capture in actual dimensions, size, weight, coordinated goods, reduce manual work and ensure fixed accuracy.

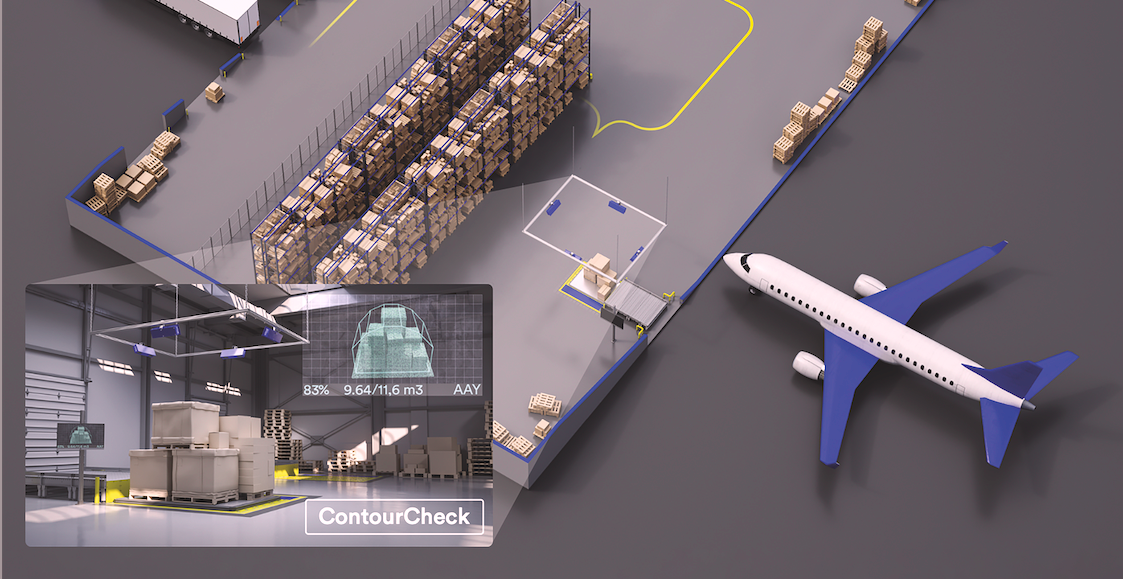

- AirFeright 3D Reactions: Cintourcheck provides 3D models of platforms during accumulation, verify subsistence compliance, improving loading factors by up to 10 percent and support auditing and demands with photo documents.

- Sustainable sustainable logistical services: Standardized programs that depend on programs with partners such as charging partners to improve packing, enhance efficiency, reduce lost space, decrease costs, and support environmentally friendly operations.

Logistics service providers have long struggled with manual charging measurement: unintended data, heavy employment operations, and delay in productivity.

“The use of a computer and AI vision, we offer in the actual and automatic time for the entire automatic data for critical charging data. This guarantees fixed accuracy-do not have” days “systems-with handcrafting significantly.”

Cind Dimensioner is a stereo camera system that wipes the goods stipulated in the movement, measuring dimensions, size, weight, and even reading parquet symbols in actual time. “It picks up length, width, length, size, weight, and barcode data while platforms are in the movement. Each charging section is documented by taking pictures, providing a visual record for reviews or claiming claims.”

3D optical reactions

For air conditions, the Cind Contourckk solution helps the logistics teams make more intelligent and faster decisions.

“It displays a three -dimensional model in the actual time of the pallet where it is built and constantly compared to the specified ocean,” explained Sunnåker. “The system provides immediate visual notes, which clearly indicates whether the pregnancy corresponds to the specifications of the airline.”

Contourckck also measures the use of size, and helps improve pregnancy and reduces waste. “To ensure tracking and guarantee quality, each complete accumulation is automatically documented by taking pictures when closing the construction, providing a visible record for operational reviews or audit or demands.”

The results are measurable. “It has been shown that our Contourckk tool improves our loading factors on board by up to 10 percent. This translates directly into a fewer flight, cost reduction, and improve sustainability.”

Logs more intelligent

With the disruption of the supply chain and the lack of employment that affects the sector, the CIND concentration is on the uncompromising automation that determines the need. “Our technology works with partners like Cargo-Planner to create comprehensive solutions,” Sunnåker. “CIND Dimnesseer Measurement of the inner Pety, and the cargo chart improves packing, and Contourche ensures quality monitoring. This interconnected approach enhances efficiency without disrupting the current workflow.”

Technology is adaptable. “Our systems depend on the programs, which means that we can offer new features without the need to change the devices,” Sunnåker explained. “This makes our solutions very developmentable and adaptable to changing requirements or new use cases.”

Reactions from customers have formed this model. “We are working closely with our customers and developing our products in direct cooperation with them. This rebound feeding episode guarantees that our technology remains compatible with the needs of the real world and constantly develops.”

Sustainable, driven by data

Since environmental fears reshape the global logistical scene, Cind Solutions pushes forward with the technologies designed not only for speed and efficiency, but for sustainability.

“With the increase in fuel and energy costs, our solutions help logistics service providers to transport goods more efficiently – such as reducing the size of the air flight by 10 percent. The less wasting area means that there is a need for fewer trucks and/or aircraft.”

Meanwhile, the documents based on images based on images and vision support in the actual time support planning more accurate and reduce losses. “Seeing the computer, along with our artificial intelligence technologies, offers actual time in movement in a small part of the cost of devices,” indicated Sunnåker. “They submit digital reports with actual pictures of the shipment, which provides complete transparency and track.”