A Global supply chains become faster, more digital and environmentally responsible, as charging planes are pushed into a new era. Airlines and operators are demanding shipping to aircraft that carry not only more, but also burn, and better adapt to advanced logistical requirements, and meet regulatory standards. In response to the response, aircraft manufacturers rethink charging from A to Z-first for fuel consumption efficiency, more intelligent shipping systems, technology-led improvement.

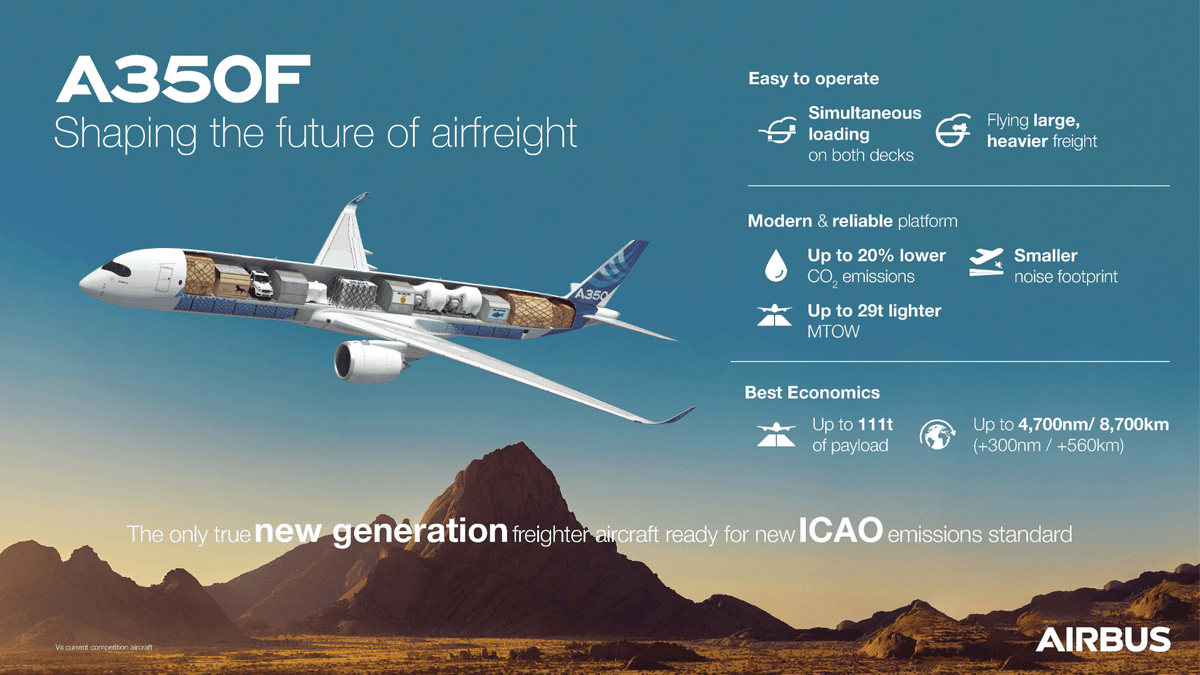

One of the most prominent examples of this transformation is A350F, charging the next generation from Airbus. The A350F is built on a fixed passenger platform but was specially designed for the facts of the goods today, and reflects how the air sector is redefined to 35,000 feet.

“Through the strengthening floor and the arduous service shipping system, the A350F can accommodate a wide range of shipping-from the temperature-sensitive drugs and live animals to heavy and traffic goods,” Krufford Hamilton, president of Airbus, said in the marketing of a cargo ship.

Lighter, stronger, cleaner

A prominent feature of A350F is fuel consumption efficiency. Airbus claims a 40 percent decrease in burning fuel compared to 747F and about 20 percent compared to 777F. These gains are achieved not only through the following dynamics and Rolls-Royce engines but also by using more than 70 percent of advanced materials, including carbon and Titanium fibers.

“These materials are incredibly strong but lightweight, allowing us to transform weight from the structure to a revenue duration. It is the victory of both emissions and economics,” Cruget Hamilton explained.

Besides New Builds, Airbus is also developing the passenger conversion program to observers (P2F), which focuses on A320 and A330 platforms. It is scheduled to replace 757s for aging, 737-400s, and A300s, providing fuel burning discounts of up to 23 percent.

“The development of the P2F A350F completes completely, which supports the update of charging fleets at all levels of charging,” said Hamilton.

It was built for the future

In reference to digitization efforts at the level of industry, the A350F includes the “digital spine”, which allows smooth integration with predictive maintenance platforms and ecosystems of data at the level of industry. Airbus highlights the use of simulation models driven by AI-alternative models-for aerodynamic designs and tension more efficiently than traditional tools.

Hamilton added: “Digital twins are already used on the side of passengers. There is no reason for not extending these capabilities to shipment, especially for urgent shipments such as drugs or live animals where improving the road is very important,” Hamilton added.

Prediction maintenance will also be very important, as Airbus indicated that unsuccessful events can be reduced by better prediction – reducing the time to stop the availability of aircraft better and improve the availability of aircraft.

On the road to hydrogen

While SAF is still the most urgent crane to remove carbon, Airbus is looking forward. All current flying aircraft are up to 50 percent of the SAF, with long -term ambitions focus on pushing hydrogen.

“We believe that fuel cell technology has the ability to provide commercial aircraft for zero emissions, but the ecosystem must develop in parallel. For this reason we are working closely with airports, organizers and fuel providers to prepare the infrastructure needed for the return of hydrogen,” Hamilton stressed.

Although viable commercial hydrogen aircraft are not likely before 2035, Airbus uses the overlapping years to develop technology behind liquid hydrogen systems and fuel cell performance.

Balance of abdominal growth and shipping

With the expectation that the charging sizes will grow by about 3.1 percent annually over the next twenty years, Airbus sees a continuous need for both shipping and abdominal ability. Despite the disturbances such as the Covid-19s, long-term expectations suggest a stable 50/50 division between shipping and cargo passengers.

“The A350F is designed to serve the most dense and most demanding ways for long distances. Its common protection with the current A350 platforms also brings maintenance advantages and operator costs.”

Since its launch in 2021, the A350F has received 63 fixed requests from 10 airline customers, giving Airbus an estimated 53 percent in the market in the new shipping sector.